AIRCRAFT TECHNICAL DESIGN & BRANDING

Aircraft Branding, Vinyl Engineering & Livery Execution — Worldwide

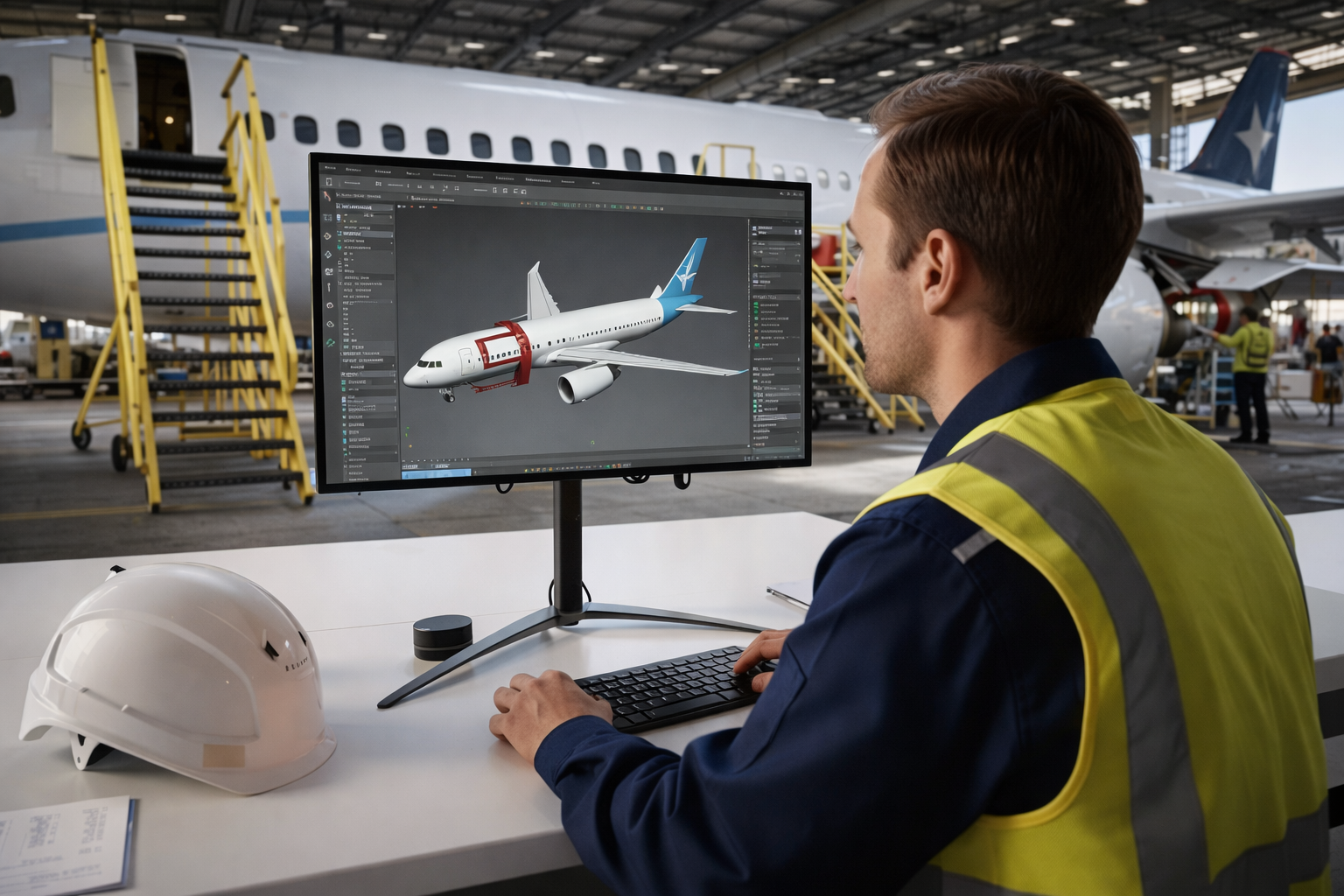

Technical aircraft branding services delivering CAD-planned livery design, vinyl removal and installation for commercial, cargo, charter and private aircraft operating globally.

DISCUSS YOUR PROJECT

Our Technical Services

Planeguard provides aircraft branding as part of its technical services. Service delivery is planned and executed using defined technical assessments and methods to ensure accurate and repeatable application on operational aircraft.

We support livery design, vinyl production, installation, removal and reapplication for fleet refresh programmes, charter entry-into-service, aircraft rebranding and cargo conversion projects.

Structured Technical Process

Every project follows a structured technical workflow, beginning with clear scope definition and technical design planning. Layouts are developed with consideration for aircraft geometry, installation areas, access panels, material capabilities and compound curves.

This approach supports efficient installation, consistent results across fleets and predictable outcomes on narrow-body, wide-body and VIP aircraft.

Single Accountable Supplier

Planeguard acts as a single accountable supplier, covering technical design through to on-aircraft installation. Clients work with one delivery team and a defined programme structure throughout the project.

This approach reduces coordination effort, simplifies procurement and supports effective integration with maintenance inputs, repaint events and aircraft conversion programmes.

Global Service Delivery

Our teams support aircraft branding projects across Europe, the Middle East, Asia, Africa and North America, operating at airports, hangars and MRO facilities.

Consistent safety standards, documentation and workflows are applied on every project, regardless of location.

Safety Management and Operational Assurance

All work is delivered using defined safety and operational procedures, supported by a company-wide Safety Management System. Planeguard operates with a 100% safety record and deploys experienced operatives trained to work in live aircraft environments.

Processes are designed to be applicable across CAA, EASA and FAA regulatory environments where required. Equipment is fit for service and materials are selected, sourced and applied using aviation-safe best practice.

This provides confidence during audits, procurement processes, inspections, lease return and operational handover, supported by clear communication and end-to-end client aftercare.

Support for Time-Critical Aircraft Projects

Planeguard has the operational capability to support a wide range of aircraft branding projects, including short-notice requirements and fast-turnaround schedules.

We support short-lead requirements for P2F cargo conversions, fleet transitions and commercial entry-into-service programmes, working within existing operational and maintenance timelines.

Our processes are designed to integrate with current project requirements, ensuring required work is delivered when needed and supporting aircraft preparation for entry into service.

Imagery shown represents typical aircraft branding environments.

Frequently Asked Questions

Can you support P2F conversion programmes?

Yes. We support P2F conversion projects by understanding programme timelines, turnaround requirements and operational constraints. Where vinyls are already available, we can assist with preparation, removal and installation. Where required, we can also provide technical design, supply and installation under a single scope.

We have a defined budget but still need the work completed. Can you support this?

Yes. We support a wide range of project budgets and can adapt the scope accordingly. Where vinyls are already produced, we can focus on aircraft preparation, exterior cleaning, machine polishing and installation while working within agreed constraints.

We require the project to be completed within a short timeframe. Is this possible?

Yes. We can support expedited schedules where required. Timelines are assessed realistically based on scope, availability and aircraft condition.

We have an aircraft with an existing full fuselage wrap that is sun-baked and difficult to remove. Can you advise?

Yes. We have previously assessed and supported the removal of aged and sun-exposed vinyl. Removal methods are selected based on aircraft condition and material behaviour. Where required, additional steps such as controlled degreasing or machine polishing may be recommended before proceeding.